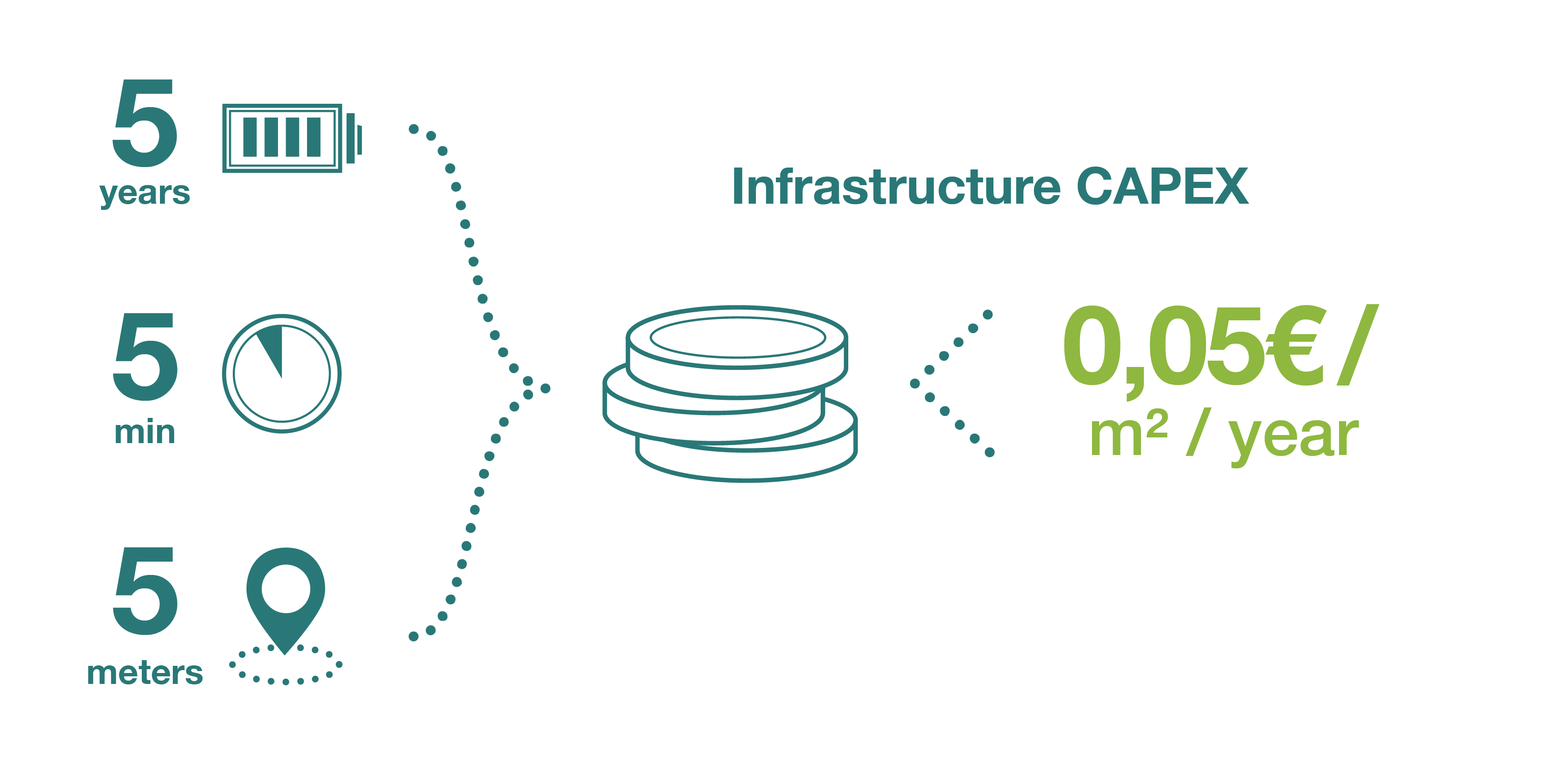

Wirepas 5-5-5 promise.

5 years of battery life

5 years of battery life The batteries in the tags/anchor tags and sensors, used for location data collection, need to last at least five years to ensure that the deployment can reach the desired return on investment (ROI).

With a regular AA-battery 5 years is easily achieved with Wirepas Mesh Location Data collection with 5-minute reporting intervals.

Even longer battery life can be achieved by using sensor triggered data collection, such as motion, methods or less frequent reporting intervals.

For most needs, location data is up to date with 5-minute reporting intervals. In most cases even 10-, 15- and 30- minute intervals are enough. It is possible to collect the data even more frequently. This will have an effect on the power consumption.

Most of the time sensor triggered data collection is recommended. The system collects the data when a change in the network happens. Benefits of sensor triggered data collection include:

Use cases in production, healthcare and storage spaces require the accuracy of a person’s visual environment which means roughly 5-10-meter accuracy, zone or room accuracy. That is enough to reduce the time used in searching for the assets in a large area, like an office building, hospital or a production floor.

For assets that require more accuracy, an easy and affordable solution is to add e.g. an LED light to the asset tag, that can be lit to guide to worker to recognize the asset they are looking for in the area with a 5 m location accuracy.

Using the 5-5-5 approach the cost sinks down to cents per square meter per year. Ask for more information on the calculation basics from Wirepas.

Low TCO is the key

Easy deployment also means lower costs. Anyone can do the installation and there is no need to hire expensive trade experts to perform the deployment.

There are ways to lower the TCO per tag per m² per year even more:

Each use case is unique in terms of the needed reporting interval or sensor triggering method, the accuracy and the battery life expectations. The 5-5-5 method acts as a baseline, but to ensure a successful deployment that fits the customers’ requirements, all the points can be altered. Whatever the use case, the costs will keep in the lower tens of cents per square meter per operational year.